Isight 2016 Win64

In today’s computer-aided product development and manufacturing environment, designers and engineers are using a wide range of software tools to design and simulate their products. Often, the parameters and results from one software package are required as inputs to another package, and the manual process of entering the required data can reduce efficiency, slow product development, and introduce errors in modeling and simulation assumptions.

SIMULIA’s Isight Solution

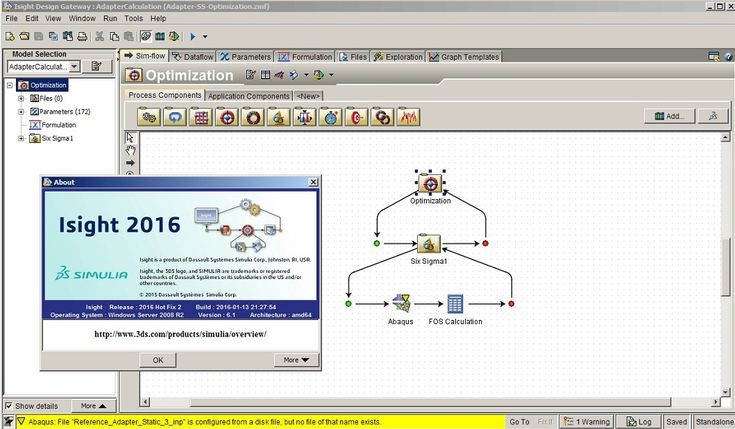

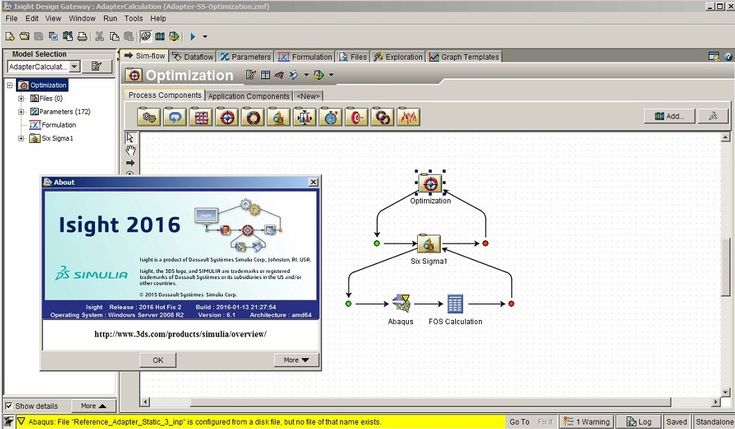

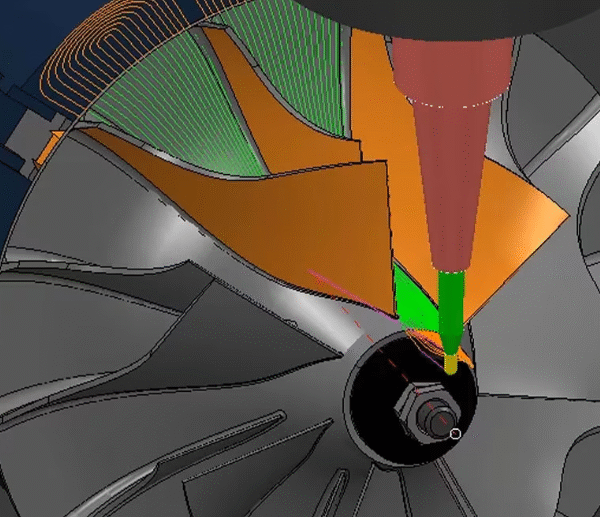

Isight provides designers, engineers, and researchers with an open system for integrating design and simulation models—created with various CAD, CAE, and other software applications—to automate the execution of hundreds or thousands of simulations. Isight allows users to save time and improve their products by optimizing them against performance or cost metrics through statistical methods, such as Design of Experiments (DOE) or Design for Six Sigma. Isightcombines cross-disciplinary models and applications together in a simulation process flow automates their execution, explores the resulting design space, and identifies the optimal design parameters based on required constraints.

Insight’s ability to manipulate and map parametric data between process steps and automate multiple simulations greatly improves efficiency, reduces manual errors, and accelerates the evaluation of product design alternatives.

Open Component Framework

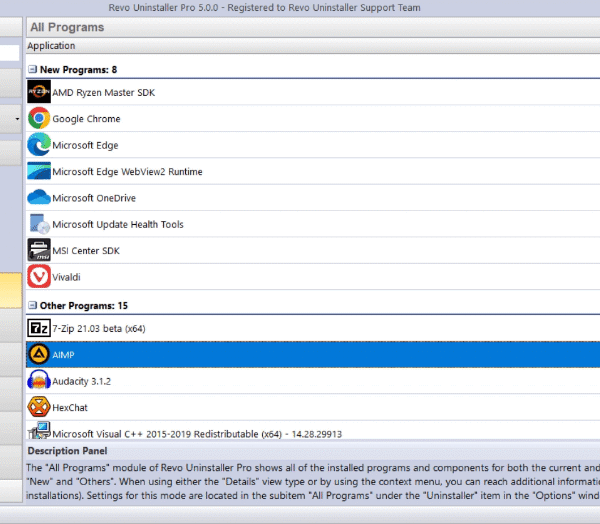

Isight provides a standard library of components—including Excel™,Word™, CATIA V5™, Dymola™, MATLAB®, COM, Text I/O applications, Java and Python Scripting, and databases—for integrating andrunning a model or simulation. These components form the building blocks of simulation process flows.

The direct link between Isight and the components allows for easy modification of a reference input deck, execution of the component, and the extraction of the output information. A full-featured development environment, based on EclipseTM, supports the development of components, whereas the open API extends additional insight capabilities. This open architecture allows SIMULIA and its partners to offer a wide range of application components that provide tighter integration with models developed in popular engineering software applications.

Here are some key features of “Isight”:

Design of Experiments

The DOE component enables engineers to quickly assess the impact of various design variables based on a set of objectives and identify significant interactions. The design data produced by DOE runs can also be used with approximation models for use with optimization methods.

Optimization

Isight provides a comprehensive selection of parallelized optimization techniques that can be applied to a variety of problems. It also includes techniques that can handle multi-objective optimization problems.

Data Matching

This process enables simulation models to be calibrated minimizing any variety of different error measures usingoptimization techniques. Target data can be imported as experimental or simulation results.

Approximations and the Visual Design Driver

Isight offers powerful real-time tools to interpolate results of computationally intensive realistic simulations. Approximation models are automatically cross-validated to ensure accurate predictions. The Visual Design Driver allows users to see their approximation models from many different views and “surf” the design space graphically and interactively.

Quality Methods

Isight provides stochastic methods that account for variations in product designs and their operating environment. The Monte Carlo simulation (MCS) component offers an accurate method to address uncertainty and randomness in the design process. It allows users to sample the design space, assess the impact of known uncertainties in input variables on the system responses, and characterize the statistical nature (mean, variance, range, distribution, etc.) of the responses of interest.

Reviews

There are no reviews yet.