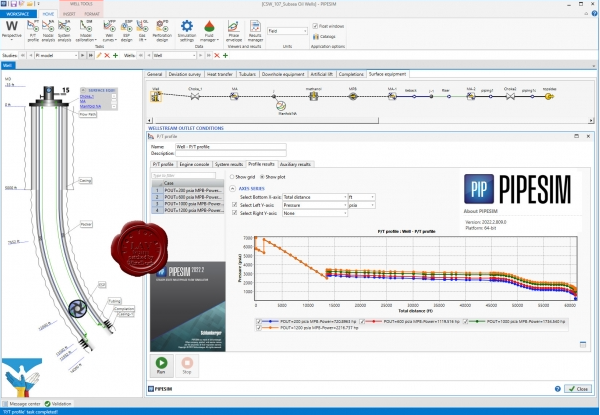

Schlumberger PIPESIM 2023.1.615 Win64

In a word, with Schlumberger PIPESIM software, the correct amount needed to achieve the challenges of fluid flow and production optimization can be calculated.

One of the biggest concerns of engineers is the safe design of wells and pipelines so that the produced fluids reach the process facilities safely and cost-effectively. The foundation of proper modeling of production systems is based on the following three main scientific areas, all of which are included in PIPESIM:

Multiphase Flow Modeling: PIPESIM employs a wide range of industry-standard multiphase current communications as well as advanced three-phase mechanical models. This model makes it possible to calculate the flow structure, fluid latency, material motion characteristics, and pressure reduction of all stations along the production path.

Liquid Characterization Modeling: PIPESIM provides two choices for the user, one is related to industry standard black oil concepts, and the other is a range of hybrid models of equation states. Depending on the application, users can choose from a wide range of features in the software to model a wide range of fluids.

Heat selection modeling: Accurate prediction of heat transfer is critical in calculating the temperature of the desired fluid properties in the system, the formation of solids, and, in principle, for all global thermal design systems. PIPESIM performs energy balance calculations calculated for a variety of heat transfer mechanisms.

Other main features of Schlumberger PIPESIM :

Ensuring safe and efficient fluid transfers: Modern manufacturing systems need designs that ensure fluids are safely and efficiently transported from tanks to process equipment. The fact that these systems exist in difficult environments, such as deep-water areas with complex infrastructure, or on large piers, adds many factors to such designs. The ability to accurately simulate a wide range of scenarios and conditions is used in the PIPESIM steady-state multiphase flow simulator, which is used as a current flow simulation tool in the design of production systems.

Production optimization: When a production system is put into operation, the ability to ensure optimal production is critical to achieving maximum economic potential. Here, too, PIPESIM software provides a complete set of workflows – from the right choice to get the job done to identifying and migrating workflow challenges and even optimizing the completed system online.

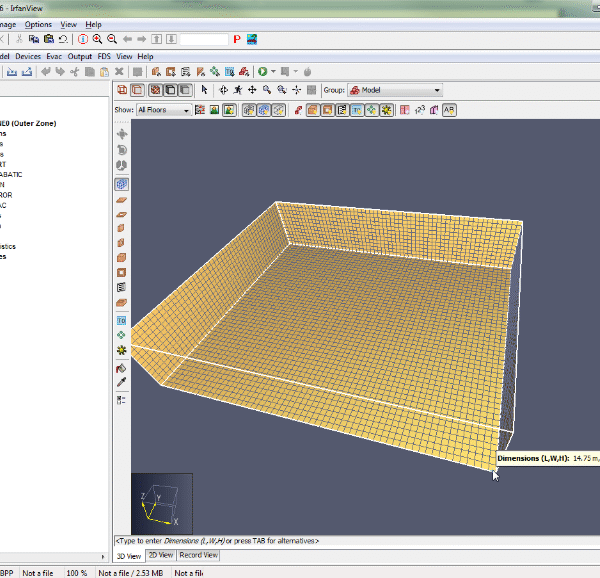

Steady-state multiphase current simulator: PIPESIM software is a steady-state multiphase current simulator. PIPESIM models multi-phase currents from the reservoir to the source. The efficiency of flow and surface line equipment can be calculated to produce complete production system analyses. PIPESIM software can be integrated with the operating software production platform of Petrel E&P and Avocet to provide a single solution and a complete simulation from tanks to production.

Enhancements in PIPESIM 2023.1

Historically, the Pipesim simulator offered the support of two main well types: production and injection. In Pipesim 2023, the new advanced well type is introduced to support complex well configurations. This new well type is considered a revolutionary step-change in the steady-state well modeling domain and facilitates the modeling of various multi-stream well configurations and smart well completions. This release includes a limited edition of this functionality, which will enable the modeling of:

• Flow control valves (For more information, see smart well completions with flow control valves.)

• Tail pipe configuration

• Tubing and annulus flow with two surface pressure conditions

• ESP separated gas in the annulus.

• Steam circulation with or without completion

• Production/injection pairs using the same well perspective

Smart well completions with flow control valves

Modeling of flow control valves (FCVs) was available in the Pipesim simulator classic (up to 2012) as a limited functionality since a single valve could be connected to one completion. In later versions, modeling of FCVs with this limitation was only available by using engine keywords. In Pipesim 2023, a major upgrade in the modeling of FCVs is introduced and enabled under the advanced well editor.

The FCV can be placed along a tubing or a tailpipe. The flow in the annulus is modeled in case the valve is placed inside the depth range of a horizontal completion or away from a single-point completion. The number of FCVs is not limited or related to the number of completions in the model. The FCV catalog was updated with all SLB valves, and with the ability to add custom valves from other manufacturers.

Enable phase ratio override on Multiflash PVT files

Phase ratio override is the ability to change the gas and water ratios at any stream inlet and neglect the phase ratios specified or calculated in the original fluid description. Previously, this feature was disabled when using a PVT file generated by using the Multiflash fluid package. In Pipesim 2023, this feature is enabled, which will facilitate, in addition to overriding phase ratio in completions, the fluid editor and in sources generating vertical flow performance (VFP) files, while a Muliflash (MFL) file is used in the model.

New GIS map backgrounds

To improve the visualization on the GIS canvas, three background modes are added to the list of base maps: white, light, and dark. These backgrounds enable the display of better contrast of the network model objects and results and hide geographical data.

Python toolkit enhancements

The following enhancements are available in the Python toolkit:

• The conda environment has been upgraded to Python 3.11.4.

• To support FCV equipment, the new search method, “find_component_objects”, has been introduced to improve performance.

Easy access to simulation result files

To improve the handling of simulation results, Pipesim 2023 offers easy access to temporary simulation results files that were standard for the legacy Pipesim simulator versions (2012 and earlier). This is now available under the results manager. In addition, the VFP tables are now stored automatically in the same model directory once a VFP task is executed.

Reviews

There are no reviews yet.